Smart Grid Patents Available for Licensing

US9885646

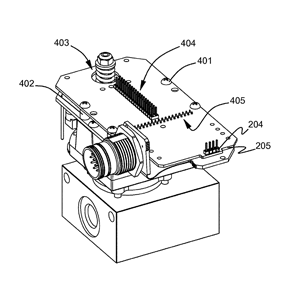

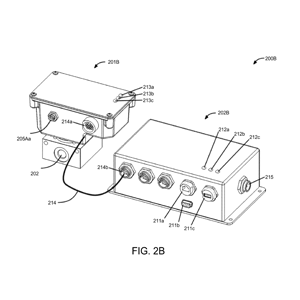

Systems and methods for calculating gas densities within a fluid enclosure are disclosed. In an example embodiment, a system includes a temperature probe for measuring an enclosure temperature in a fluid enclosure filled at least in part with a fill gas, an atmospheric pressure sensor for measuring the atmospheric pressure outside the fluid enclosure, a gas sensor for measuring an enclosure pressure within the fluid enclosure, and a controller for calculating a fill gas density within the fluid enclosure based at least in part on the enclosure temperature, the atmospheric pressure, the enclosure pressure, and a gas coefficient of the fill gas.

US9851277

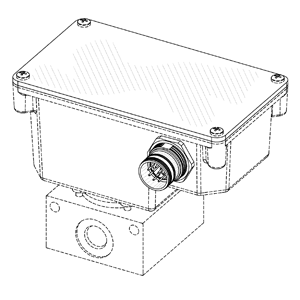

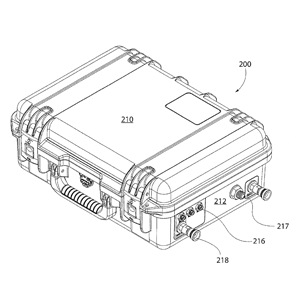

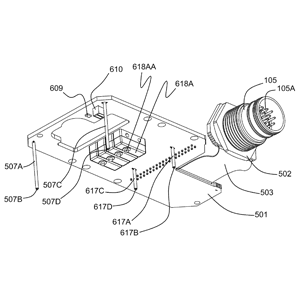

Mechanical, electronic, algorithmic, and computer network facets are combined to create a highly integrated advanced gas sensor. A sensor is integrated into switchgear housings. These sensors integrated into high voltage switchgear products, deployed by electric utility end users in replacement and expansion cycles, function to detect and mitigate atmospheric pollution caused by leaking SF6. As its associated gas insulated tank is charged with 10 to 350 lbs. of SF6, each gas sensor monitors its local cache of gas, accurately sensing and computing fractional percentage losses (emissions) and gains (maintenance replacement) in SF6 mass, storing data in onboard data logs, and communicating data when triggered by detection events or in response to remote requests over a hierarchical communications network, a process that continues without labor until a fractional leak is automatically detected and reported creating the opportunity for early leak mitigation.

US9696248

Mechanical, electronic, algorithmic, and computer network facets are combined to create a highly integrated advanced sensor that monitors the gas density, state-of-repair, and events associated with switchgear. Measurements of gas pressure, atmospheric pressure, gas temperature, are used with models of the non-ideal behavior of a particular gas to realistically estimate gas density. A hierarchical system of signal processing optimizes measurements working within high-frequency, real-time, short-term, medium-term, diurnal, long-term, and historical timeframes and overcomes measurement errors present in real-world applications. The time at which a condition such as gas density will reach a particular level is calculated. Events such as threshold attainments and switchgear operation are detected. A large memory stores all raw data values allowing flexible re-processing and verification at any future time. Instantaneous as well as logged information is communicated in convenient formats over a selected digital network. An embedded web server provides a familiar graphical user interface.

US9335232

Mechanical, electronic, algorithmic, and computer network facets are combined to create a highly integrated advanced gas sensor system. The sensor system, utilized with gas insulated high voltage switchgear products, deployed by electric utility end users in replacement and expansion cycles, function to detect and mitigate atmospheric pollution caused by leaking SF6. As its associated gas insulated tank is charged with 10 to 350 lbs. of SF6, each gas sensor monitors its local cache of gas, accurately sensing and computing fractional percentage losses (emissions) and gains (maintenance replacement) in SF6 mass, storing data in onboard data logs, and communicating data when triggered by detection events or in response to remote requests over a hierarchical communications network, a process that continues without labor until a fractional leak is automatically detected and reported creating the opportunity for early leak mitigation.

US9212966

Mechanical, electronic, algorithmic, and computer network facets are combined to create a highly integrated advanced gas sensor. A sensor is integrated into switchgear housings. These sensors integrated into high voltage switchgear products, deployed by electric utility end users in replacement and expansion cycles, function to detect and mitigate atmospheric pollution caused by leaking SF6. As its associated gas insulated tank is charged with 10 to 350 lbs. of SF6, each gas sensor monitors its local cache of gas, accurately sensing and computing fractional percentage losses (emissions) and gains (maintenance replacement) in SF6 mass, storing data in onboard data logs, and communicating data when triggered by detection events or in response to remote requests over a hierarchical communications network, a process that continues without labor until a fractional leak is automatically detected and reported creating the opportunity for early leak mitigation.