Battery Electric Vehicle Patents Available for Licensing

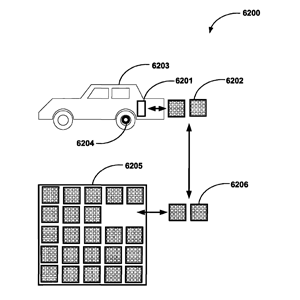

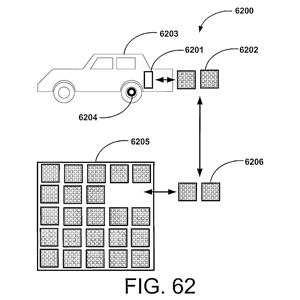

US7948207B2

A process for operating an electric vehicle, said electric vehicle includes a plurality of battery modules, comprising: a step for measuring, periodically, the state of charge and energy content of each battery module of said plurality of battery modules; a step for returning one or more of said plurality of battery modules at an electric filling station and, a step for receiving credit for each of said battery modules and said energy remaining in each of said battery modules at the time each of said battery modules is returned.

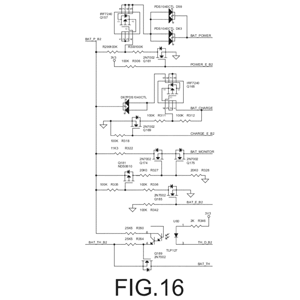

US8025118B2

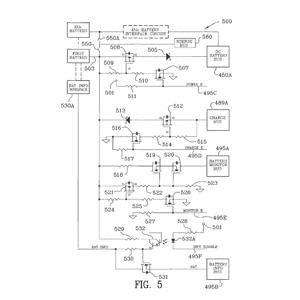

A battery electric vehicle power supply system in combination with a battery electric vehicle motor system, comprising: a microcontroller; at least one removable cartridge battery pack, a battery bus, a charge bus, and a battery information bus; switches between each of said at least one removable cartridge battery pack and each of said battery bus, charge bus, and, battery information bus; said microcontroller selectively connecting or disconnecting each of said at least one removable cartridge battery pack from each of said battery bus, charge bus, and battery information bus by controlling said switches; said battery bus being connected to said battery electric vehicle motor system so as to provide power for said motor system; said charge bus being connected to said battery electric vehicle motor system so as to recapture regenerative energy from said system for the purposes of recharging said at least one removable cartridge battery pack.

US8698452B2

A battery electric vehicle service station, comprising: at least one removable cartridge battery pack, a battery bus, a charge bus, a battery information bus, switches between each of said at least one removable cartridge battery pack and each of said battery bus, charge bus, and battery information bus, and a microcontroller, said microcontroller selectively connecting or disconnecting each of said at least one removable cartridge battery pack from each of said battery bus, charge bus, or battery information bus by controlling said switches.

US8710795B2

A process for operating an electric vehicle comprising the steps of: measuring state of charge of each of a plurality of battery modules, each of said plurality of battery modules includes specified limits for charging and discharging duty cycles, respectively, said specified limits of each of said plurality of battery modules include a predefined low state of charge and a predefined high state of charge, and, said predefined low state of charge and said predefined high state of charge are calculated by a microprocessor based on known battery chemistry, cell size, nominal voltage and a set of measured values including operating voltage of each of said plurality of battery modules, operating current of each of said plurality of battery modules, and operating temperature of each of said plurality of battery modules;

US8796987B2

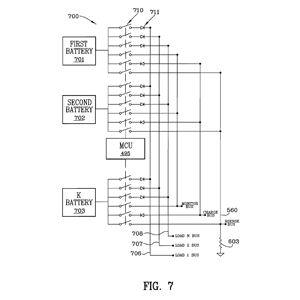

A process for operating an electric vehicle, said electric vehicle includes a plurality of battery modules, comprising the steps of: utilizing a battery module interface circuit between each of said plurality of battery modules and an information bus; operating, utilizing a controller, said battery module interface circuit between each of said battery modules and said information bus selectively interconnecting said battery modules to said information bus for measuring, periodically, the state of charge and energy content of each battery module of said plurality of battery modules; each of said battery module interface circuits includes a first switch interposed between a battery information interface circuit and said battery information bus, said controller selectively enabling and closing said...

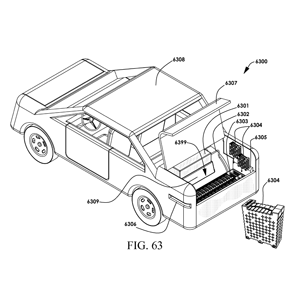

US8872474B2

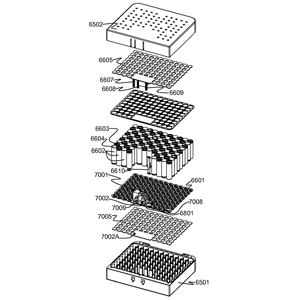

A fail safe battery pack, comprising: a first housing and a second housing affixed together; a plurality of battery cells residing within said first and said second housings, said plurality of battery cells engaging said first and second housings, said plurality of battery cells are not movable with respect to said first and second housings; a first printed circuit board and a second printed circuit board; said first housing includes a first lattice structure of battery cell supports; said second housing includes a corresponding second lattice structure of battery cell supports; a variable bias device resides in said first lattice structure of said first housing and engages said first lattice structure; said first printed circuit board resides in said first lattice structure of said battery supports and engages said first variable bias device;

US9381822B2

A process for operating an electric vehicle comprising the steps of: measuring the state of charge of each of a plurality of battery modules while said battery modules are on-board said electric vehicle, each one of said plurality of battery modules being in parallel with one another; measuring the power demand of an on-board electrical drive system of said electric vehicle; selectively coupling the most highly charged battery modules to said on-board electrical drive system more often than lesser charged battery modules when said on-board electrical drive system is under load requiring power from said plurality of battery modules; selectively coupling the least highly charged battery modules to said on-board electrical drive system more often than more highly charged battery modules when said on-board electrical drive system is sourcing power under conditions from an on-board regenerative power source;

US10109888B2

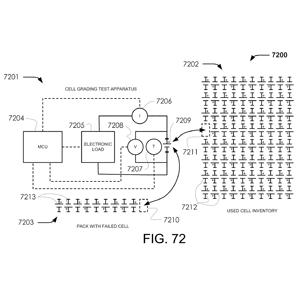

A process for operating a battery pack service station to repair a battery pack, said service station includes a controller, said battery pack includes a plurality of cells, comprising the steps of: determining, using said controller, a failed cell of said plurality of cells of said battery pack; removing said failed cell from said battery pack; determining, using said controller, a characteristic of a non-failed cell of said battery pack; selecting a replacement cell; determining a characteristic of said replacement cell using said controller; comparing, using said controller, said characteristic of said replacement cell to said characteristic of said non-failed cell, and deciding, using said controller, whether said replacement cell can be substituted for said failed cell in said battery pack.