Electrical Test Instruments

Abstract

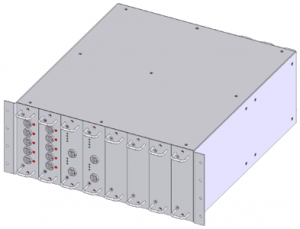

Modtech and technology partners developed the world’s most accurate, serviceable, configurable, resistance thermometry instrument.

Background

The National Institute of Standards and Technology (NIST) oversees realizing, maintaining, and disseminating the International Scale of 1990 (ITS-90). The Standard Platinum Resistance Thermometer (SPRT) Calibration Laboratory of the NIST Thermometry Group describes calibration services and methods that utilize commercially-available AC resistance-ratio bridge instruments. Modtech led the engineering and building of a next generation instrument aimed at improved resolution, accuracy, versatility, maintainability.

Client's Goal

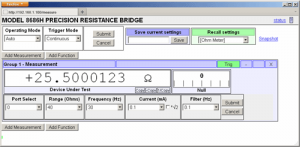

To achieve its SPRT calibration mission, NIST was using AC thermometry bridge products from off-shore manufacturers. These instruments were expensive, lacked reliability, and were not repairable in a timely fashion. The client wished to overcome these limitations by developing a new instrument, Model 8686H, that would provide measurements of equal or improved fidelity. The unit is to be capable of measuring resistances from 0 to 400 ohms with better than 0.1 µΩ resolution and an accuracy of better than 0.1 ppm. It will have advanced features such as a built-in webserver, USB interface, and built-in complex functions. Examples of such complex functions are complimentary ratio-check and zero ohms power extrapolation for sensor measurements. The embedded webserver introduces features never available in a Precision Resistance-Ratio AC Bridge.

Challenges

Utilize trusted predecessor technology: as a starting place for the design of a next generation instrument. Historical prototype instruments are available for study, but documentation pertaining to these complex units is scant.

Measurement range, resolution, and accuracy: The instrument will measure: 12 Ω range with resolution of 0.01 µΩ, 40 Ω range with resolution of 0.1 µΩ, 120 Ω range with resolution of 0.1 µΩ, all with accuracy of 1 ppm, and 400 Ω range with resolution of 1 µΩ and accuracy of 2 ppm.

Reliability and ease of repair: The instrument must be reliable, and repairs must be simple and fast. Module level replacement repair modality is preferred.

Teamwork: Modtech seamlessly integrated with a small business partner to manage the project and perform the engineering and design tasks required. Communicating technical and commercial ideas in a clear and accurate manner was key.

Ideation

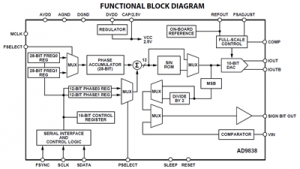

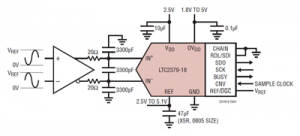

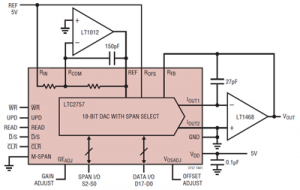

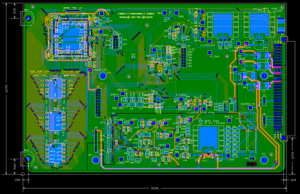

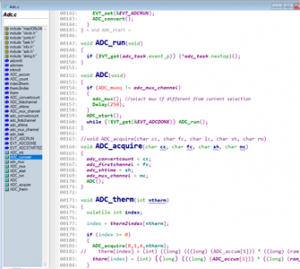

A multistage-transformer-based AC bridge with MCU and FPGA controlled agile DAC excitation and high-resolution ADC detection is used to achieve the combination of resolution and accuracy required for the application.

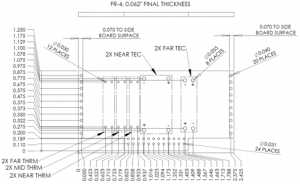

An advanced reference oven module: utilizing thermoelectric-based temperature management was conceived to provide a stable, room temperature environment for a bank of five (5) ultra-precision reference resistors critical to the instrument.

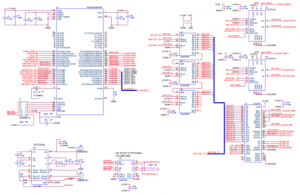

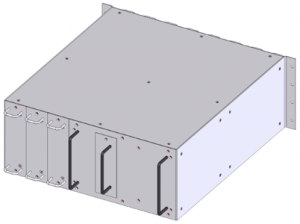

A unique architecture: with smart digitally controlled modules interconnected by a high-performance, hybrid, digital-analog backplane was conceived. PCB designs and backplane module interconnection were selected to eliminate unreliable and hard-to-repair point-to-point wiring. Quick connect, interchangeable modules will make instrument repair and reconfiguration easy and foolproof. Distributed processors on each module and a host processor supporting inter-module communications and user interfaces allow very efficient real-time data acquisition, processing, and communication.

An embedded webserver: running on the host will sallow a user to enlist any hardware platform having a standard web browser as the graphical user interface (GUI). No proprietary software or applications need to be loaded.

Engineering and design deliverables

Brainstorm approaches to system architecture.

Perform extensive component evaluation. Engineer BOM.

Develop detailed 3D models.

Engineer PCBA designs for ten (10) complex modules.

Engineer product firmware codes and webserver GUI.

Manufacture pilot production units